Real Vs. Faux Concrete Walls: Which One Is Best For Your Space?

Recreating the concrete look

Have you ever looked at a modern, industrial space with concrete walls and wished you could recreate the look in your own home? Or maybe you have a commercial space and want the cool, rugged look of concrete but can’t add the structural supports necessary to install it.

Whether the project is big or small, indoors or out, the look of concrete cladding is easier to achieve than you might think.

Let's walk through some of the pros and cons of three different options for getting the concrete look for your walls: poured concrete, real cast thin concrete panels, and faux concrete panels.

1. Real poured or pre-cast concrete

Poured concrete fireplaces

When it comes to retaining walls or basement foundations where strength and structural integrity are key, poured or precast concrete will be your best bet. However, if you want to add a concrete look to an existing structure, poured concrete might be too difficult and too costly.

Unless you’re a contractor yourself, you will need to hire a professional to create a substructure and pour and install the wall for you, which is where the dollar signs start to multiply.

Style Options For Poured Concrete

There are a number of different options when it comes to concrete walls, but typically you will see plain poured concrete, precast concrete, or board-formed/stamped concrete.

Plain poured concrete has a smooth (ish) finish and is the only way to get a completely seamless look.

Precast will have visible joists or posts that each precast panel attaches to.

Board-formed concrete is a trend in modern design that uses wood planks to create a natural wood grain texture in a poured concrete structure. A similar concept is stamped concrete, which typically takes on the look of stone.

A poured board-formed concrete half wall

Benefits of poured or precast concrete walls

- Most authentic option

- High structural integrity

- Fireproof and waterproof

- Ability to make a completely seamless look

Downsides of poured or precast concrete walls

- At risk of honeycombing, cracking, and other denigration

- Requires a professional contractor

- Requires specialized molds and/or structural supports

- Expensive to install

- Too heavy and inaccessible for many areas of a typical home without foundational support

- Can take up to 60 days to complete due to curing time

2. RealCast Thin Concrete Wall Panels

RealCast Concrete Panels on an outdoor wall

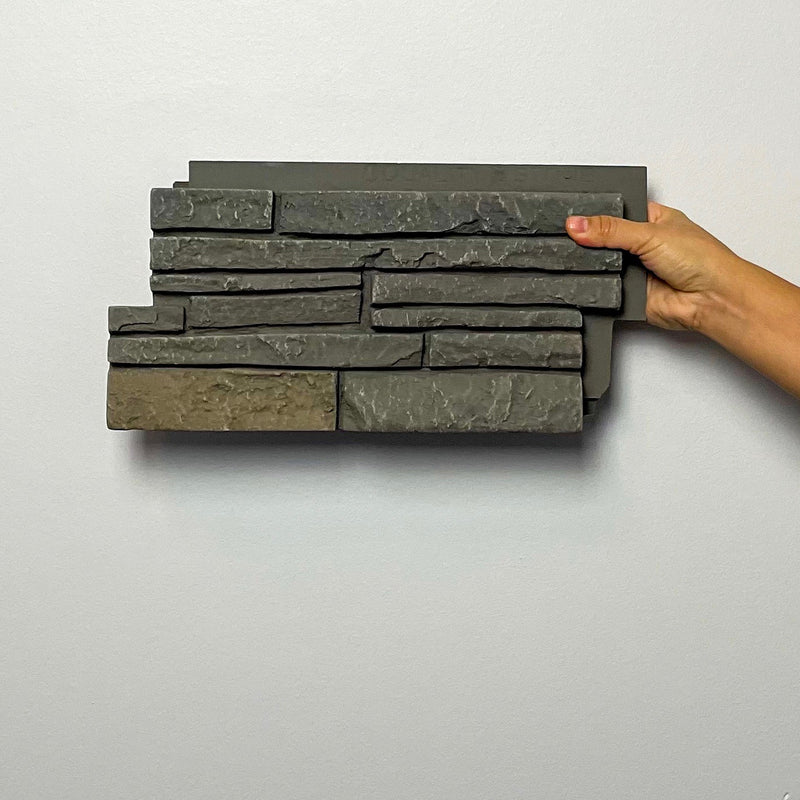

RealCast wall panels are made using real concrete in an ultra-thin mold that is reinforced with fiberglass mesh, making them incredibly durable while still being super lightweight and easy to install. They look just like real concrete because they ARE real concrete, which also makes them fireproof and waterproof.

Style Options For RealCast Concrete Panels

Out of the box, you have three style options for RealCast: flat slabs, slabs with anchor holes, or board-formed panels, like what designer James Judge used on his outdoor courtyard wall below.

For large projects, custom styles are also available.

A recent project from James Judge using our RealCast Board-Form panels.

A recent project from James Judge using our RealCast Board-Form panels.Benefits of RealCast Thin Concrete Panels:

- DIY friendly

- Lightweight

- Can be installed directly on an existing surface; No foundational or structural supports required

- Easy to install with a strong adhesive and brad nails

- Waterproof--can be used in bathrooms or other areas with direct water contact

- Fireproof--can be used directly around fireplaces

- Can be installed indoors and outdoors

- Easy to cut with standard carpentry tools

- Real concrete feel & look

- Can be installed on nearly any surface or substrate

Downsides of RealCast Thin Concrete Panels:

- More expensive than faux concrete

3. Faux Concrete Wall Panels

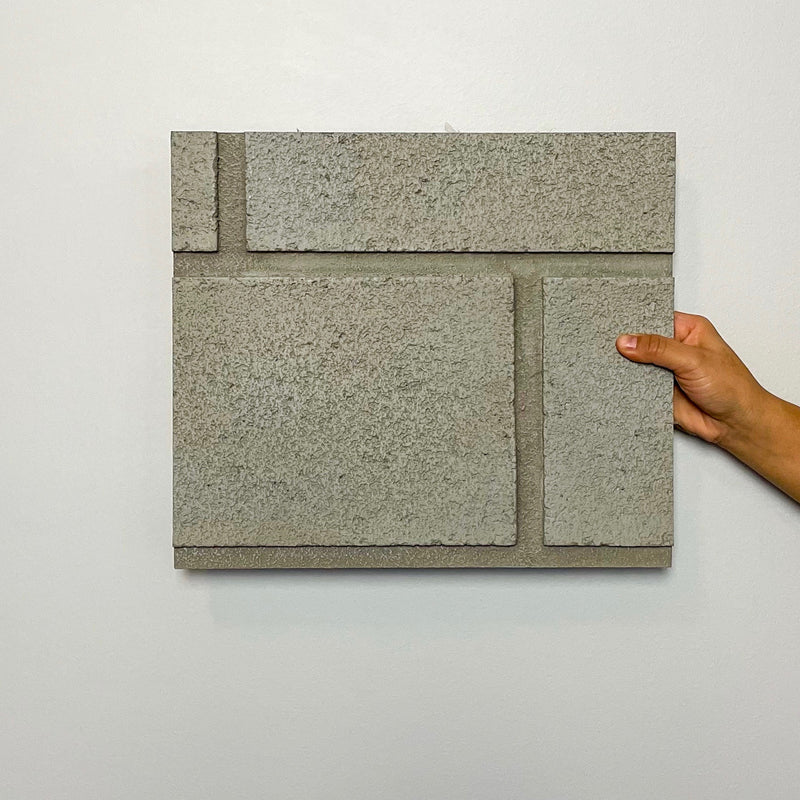

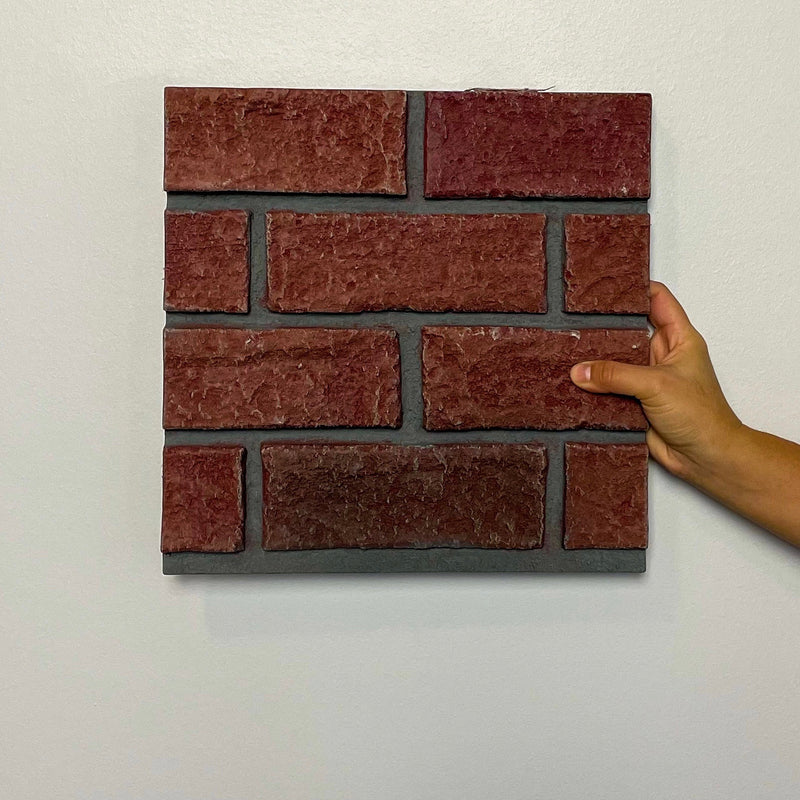

Yes, it is possible to create a real concrete-look without actually using real concrete. Our URBANCONCRETE faux concrete wall panels are made using a high-density polyurethane, making them only about 1lb per square foot.

Each panel is made by pouring polyurethane into real concrete molds and is then hand painted to create an authentic look.

This is the easiest option in terms of installation, though it is more limited than RealCast in terms of usage because it is not fireproof.

Style options for URBANCONCRETE Faux Concrete Panels

We have multiple style options in our faux concrete panels, including slabs (with or without anchor holes), cinderblock, and stucco.

Again, customizations are available for large projects if needed, including exterior panels.

Because of the tongue and groove format of the panels, there is a small gap in between panels, which defines each individual panel & creates texture.

Benefits of URBANCONCRETE Faux Concrete Panels:

- DIY friendly

- Ultra lightweight

- No foundational or structural supports required

- Easy tongue-and-groove installation - use either nails, screws, or a strong adhesive

- Can be installed in a temporary fashion using double-sided tape

- Easy to cut with standard carpentry tools

- Class-A fire rated for use around some gas fireplaces

Downsides of URBANCONCRETE Faux Concrete Panels:

- Shouldn’t be used in areas with direct water contact, such as showers

- Does not feel as hard as real concrete to the touch

- May not be usable on all fireplaces--always check your fireplace manual before installing

So what option should you choose for your concrete wall?

If you need structural integrity for your project, such as for a retaining wall, poured concrete is going to be your best choice.

However, if it’s just the look you want, RealCast Slab, RealCast Board-Form, or URBANCONCRETE Faux Concrete are much more accessible options, both cost-wise and install-wise.

If your wall will be outdoors, in a wet environment like a shower, or you just want the cool touch of real concrete, RealCast Slab or Board-Form is your best option.

If cost and ease of use are your biggest considerations, faux concrete panels will be your best bet.

Still having a hard time deciding? Take a look at our comparison chart below, or order samples of both URBANCONCRETE and RealCast Slab / Board-Form panels to see what product will fit the bill.